Subtotal: $87.92

What is Material Handling:

In Industries Factories Warehouses, “Moving”, “Loading”, and “Unloading” of raw material and goods with the help of some mechanical equipment comes under the umbrella of Material Handling.

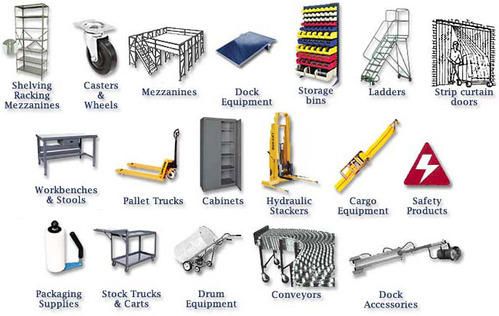

Material Handling Equipment

Materials handling equipment are mechanical equipment that are utilized in moving, storing, controlling, and protecting products and materials throughout the cycle processes of manufacturing, distributing, consuming, and disposing.

Some Categories of Material Handling Equipment

- Bulk material handling

- Engineered systems

- Industrial trucks

- Storage and handling equipment