If you are unfamiliar with SCADA Systems, its functionality, and its application and you have a lot of questions tickling in your mind, then you came to just the right place. Hope this blog may answer some of your queries and give you a clearer understanding.

What is SCADA?

Supervisory Control and Data Acquisition (SCADA) is a combination of software, hardware, and communication system that aid industries in monitoring data and processes, maintaining efficiency, processing data to make better decisions, and communicating system errors and issues to reduce downtime and catastrophic failures. It enables industries to:

· Automated Monitor, Control, and management of industrial operations locally or remotely.

· Monitor, record, and process real-time data

· Using human-machine interface (HMI) software, directly interact with equipment such as sensors, motors, valves, pumps, and more

· Record events into a log file

· Report generation

SCADA Architecture

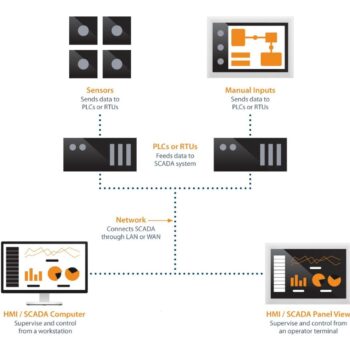

The basic SCADA architecture begins with programmable logic controllers (PLCs) or remote terminal units (RTUs). PLCs and RTUs are microcomputers that interface with an array of items such as machines, sensors, HMIs, and other end devices, and then transport information signals from objects to computers or the cloud with SCADA software. SCADA software processes distribute, and display data, assisting operators and other staff in analyzing data and making critical decisions.

How can SCADA Help me?

SCADA can provide machine operators and company management with numerous helpful production insights and allows them to reduce production waste, minimize downtime and improve overall efficiency. It enables the higher management to take a data-driven decision that leads to more production, better process control, and lower costs. For example, the SCADA system quickly alerts an operator that a batch of products is showing a high rate of errors. To investigate the causes of the problem, the operator stops the operation and uses HMI to inspect the SCADA system. When the operator examines the data, he realizes that Machine 4 was not working properly. The capacity of the SCADA system to alert the operator to a problem aids him in resolving it and preventing additional product loss.

With real-time notifications and alerts, operators and backup systems may respond to and manage any machine failure or faults which can reduce production downtime and save from any catastrophic event.

SCADA reduces human error by automating common, laborious routine operations that were previously handled by a human. Precise and automated monitoring and control of equipment and processes almost eliminates human error chances. Furthermore, SCADA systems facilitate monitoring and control across wide geographical areas that a company may not have enough manpower to cover.

Applications of SCADA

Supervisory control and data acquisition (SCADA) systems are used in a variety of applications in many types of organizations. From simple configurations to large complicated installations, all are possible with SCADA. Look around and you will discover the SCADA system working behind the scenes across a wide range of processes. SCADA systems are helping to save money and time by decreasing production waste and increasing overall efficiency whether maintaining the refrigeration systems at the local supermarkets, assuring production and safety at a refinery, meeting quality standards at a wastewater treatment facility, or even tracking your energy consumption.

Some of the industries that use SCADA in their daily operations include:

Water/Wastewater Systems

Utilizing efficient and precise water and wastewater monitoring and controlling systems is critical for your community with clean, cheap water.

From source to tap, and from your drain back to the source, the water we use every day is meticulously monitored to ensure that overall water quality is consistent and in compliance with state and federal regulations.

It helps to monitor and control water pumped from wells and processed at water treatment plants. Additionally, water SCADA systems also regulate water pressure by controlling booster pumps.

Lift stations that pump wastewater to treatment plants are also monitored and controlled by SCADA systems and in the treatment facility, it is used to control the treatment process step by step. SCADA helps to detect the smallest inconsistencies in day-to-day operation to make water and wastewater systems more energy efficient.

Electric Generation, Transmission and Distribution Systems

From fuel input to the power plant to electrical power output, SCADA systems are used to monitor every step of energy generation. It enables Electrical power plants to adapt to demand variations in real-time. SCADA Systems also allow electrical transmission companies to monitor and regulate electrical power that has to be transferred over a long distance.

SCADA is also used for safety and protection purposes. In case of line fault, the system will attempt to clear the fault and restore power as soon as possible. It is also used to monitor and control electrical substations and distribution lines in electric distribution networks.

Oil and Gas Systems

Oil and gas, unlike electric and telecom systems, transfer a tangible material through their infrastructure across a large region. SCADA is used in the oil and gas industry to monitor wells and pumping stations, as well as distribution pumping pressure and pipeline flow. SCADA software is required for safety reasons in addition to monitoring and controlling compressor stations. It is utilized to identify abnormalities and prevent catastrophic events from occurring.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Manufacturing Plant Systems

All plant operations are accurately controlled using SCADA. For example, SCADA may be used to monitor and control temperature, pressure, and humidity. It may also be used to keep track of manufacturing lines to verify that output targets are reached. SCADA can also operate assembly-line robots and track raw material usage, helping in supply chain management.

Food Production Systems

To ensure food quality and meet production goals, SCADA systems are playing a crucial role nowadays. Every stage of food preparation is monitored and controlled. SCADA may be used to regulate the precise mix of materials, as well as the time and temperature needed to process meals to ensure a quality consistent finished product. This keeps food from spoiling as a result of a heating process that was a few degrees off. SCADA applications are especially vital in the food sector to prove that the manufacturing process fulfills industry standards and follows government rules.

Mass Transit Systems

SCADA is also used extensively in mass transit systems. It is used by railways, subways, and tramways to time their operations and manages their switches, allowing locomotives and carriages to pass each other securely. Train crossing signals can also be controlled from afar. SCADA is also used in traffic control systems to improve traffic flow and safety.

Conclusion

SCADA systems are indispensable components in most industries. It is used in almost all industries to automate the control of processes and machines that would otherwise be too complex or to be controlled manually. Through sensors and measuring devices, SCADA systems can detect abnormal parameters or alarms and automatically respond with a pre-programmed control function.

AMPS is providing high-quality, reliable, and reductant SCADA, Control, and Automation equipment such as advanced programmable Logic Controllers (PLCs), Remote I/Os, and SCADA systems from the top manufacturer for complex industrial processes, machines, and high-performance production lines at the lowest cost.

As a 100% client-dedicated company AMPS is constantly working to identify ways to provide you with the quality electrical, material handling, lighting, HVAC, landscaping, and building supplies equipment and services you need, on time and at a competitive price.

AMPS provides internal training programs designed to keep our sales and support teams up to date on emerging technologies and the product solutions we provide. Our extensive product knowledge and services offered help the AMPS Associate meet the customer’s specific needs.